Equipment

Pick & Place machine

Raytex Electronics use a pick & place machine operating with large variety of components which allows us to switch between projects quickly. The machine uses a visual alignment system with 2 cameras. Small component cmaera (SCC) has linear sensor for inflight component alignment with inbuild CMOS chip and illumination. Large component camera (LCC) is stationary attached and recognizes components with dimensions up to 50mm х 50mm and 20mm height.

Technical specifications:

- Up to 120 intelligent tape feeders from 8mm to 44mm tape width

- Vibration/stick feeders for plastic sticks up to 50mm wide

- 145mm х 355mm tray feeder for large components

- Placement accuracy: 16.7µm @ 1σ, 50µm @ 3σ with 1µm encoders

- Placement rate: 4500 components/hour

Requirements and limitations

To PCB:

- Size: min 30mm х 30mm, max 350mm x 450mm

- Thickness: min 0.5mm, max 3.2mm

- Maximum warpage: 0.5mm up, 1.0mm down

- Maximum weight: 6kg

To components:

- Maximum height: 20mm

- Maximum size: 50mm х 50mm

Stencil printer

- Manual or semi-automatic printing

- Magnetic table with vacuum clamping pins

- Maximum printable area: 420mm x 370mm

- Table adjusting: linear (X,Y) +/-6mm, angle +/-2.5°

- Accuracy: +/-20µm

Reflow oven

- Conveyer chain with 5mm pins for singlesided/doublesided boards

- Maximum PCB width: 390mm

- Tunnel length: 950mm

- 8 independently controlled heating zones - 4 top and 4 bottom

- Air ioniser for ESD safe reflow soldering

- Integrated cooling zone

Dispenser

A desktop machine for quick soldering paste dispensing for PCB prototypes or small production series. It uses integrated components library which speeds up dispensing process. Instead of moving the product on a moveable table, it has a dispense valve that moves in X, Y and Z directions. The machine has an integrated camera for fudical recognition.

Specifications:

- Work area: 320мм х 420мм

- Paste dispense speed: 12 000 dots/hour

- Maximum warpage: 1mm up, 1mm down

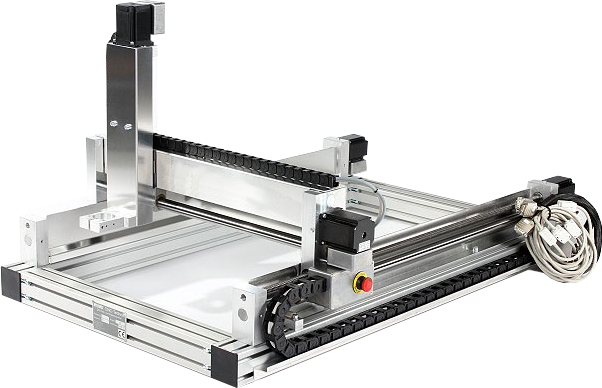

3D CNC

The machine is capable of 2D or 3D milling/engraving of aluminum, steel, wood, rock, plastic etc.

Specifications:

- Work area: 1050mm х 510mm

- Driven by 4 step motors

- Max speed: 3000mm/min.

- Accuracy: 0.003mm (1/10 step)

- Backlash: +/-30µm (0.03mm)

- Maximum travel: X=720mm; Y=420mm; Z=110mm

- Referential and travel cut-offs to all axis